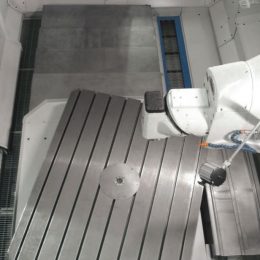

5 AXES MILLING MACHINE “T COLUMN” TYPE WITH AUTOMATIC PALLET CHANGER

CNC Milling Machines / Highlights / Milling Machines /

TECHNICAL DATA:

CNC Heidenhain Tnc 426 digital

TRAVELS:

X axis longitudinal travel: 3.500 mm

Y axis transversal travel: 1.600 mm

Z axis vertical travel: 2.000 mm

ROTARY TRANSLATION TABLE:

Dimension: 1.600 x 2.000 mm

T-slots: 22H8 (central slot 22H7)

Maximum loadable weight: 15.000 kg

KOSMO 5000 AUTOMATIC TWO-ROTATIVE HEAD:

Continuous power: kW 28

KOSMO head spindle speed: 5.000 rpm

Tool cone: DIN 69871-A50

Tie rod: DIN 69872-28 (50)

AXES (DIGITAL):

Nominal continuous torque (X axis = 3,500): Nm 70

Nominal continuous torque (Y axis): Nm 70

Nominal continuous torque (Z axis): Nm 27

Rapid speed (X, Y, Z axis): m/min 18

TOOL CHANGER:

Tool places: N° 60

Max tool diameter: 125 mm

Max tool diameter with free adjacent places: 240 mm

GENERAL:

Max machine weight: 27.000 kg

Max installed power: KW 48

Machine equipped with:

• KOSMO 5000 universal bi-rotary automatic head: indexed positioning, oil recirculation lubrication, speed 5,000 rpm, ISO50

• Electronic head thermal expansion compensation device

• Automatic locking of the pedal tool

• Chain tool magazine with 60 positions

• Electronic flyer mod. HR410

• Twin pallet changer in front of the machine with fairing

• Medium pressure refrigeration through the spindle (15 bar)

• Belt chip conveyor

• Semi-complete fairing

• Instruction manuals and CE declaration

Year of construction: 2002

PALLET CHANGE FEATURES:

• TOTAL PALLET CHANGE time = 180 sec.

o 32 sec = pallet deposit and removal time from the base (5 m/min);

o 16 sec = rapid slide extraction time (without pallet);

• pallet centering on two cemented and hardened conical pins;

• pressurization of the pins for cleaning and centering control;

• rubber scrapers along the entire perimeter of the support areas between the pallet and the table;

• protection of the pallet change area with railing and interlocked micros on the access door;

• push button panel outside the area for starting the cycle;

• internal pushbutton panel with main functions for manual movements;

• piece change area separated from the chip area by automatic doors;

• coolant collection tanks around the pallets in the part change areas.